The Tucker 48 (named after it’s model year) was an advanced automobile conceived by Preston Tucker and briefly produced in Chicago in 1948. This article is not intended to be a complete story about either the car or it’s namesake, but rather just to present some of the facts about this car.

The Car’s Design:

The initial car design was started by George S. Lawson in the summer of 1944. Lawson worked on the project for over a year-and-a-half before his design debuted publicly, about February 1946. Lawson was named the Tucker Corporation’s “chief stylist” in February 1946, immediately upon the Corporation’s formation. In December 1946, Lawson resigned from the Corporation after a disagreement with Preston Tucker. It was only then that Alex Tremulis was hired and further developed Lawson’s design. Initially, Tremulis had a three-month contract, Tremulis’ efforts during this phase of design development was featured in a full page advertisement run in numerous national newspapers in March 1947.

Tremulis’ design was based directly upon the work of George Lawson, but incorporated his own artistic flair. Next, Preston Tucker hired a team of five designers (Read Viemeister, Budd Steinhilber, Tucker Madawick, Hal Bergstrom and Phillip Egan) from J. Gordon Lippincott, who updated Tremulis’ design just as Tremulis had done with Lawson’s. After a month’s absence, Tremulis was rehired and the two independent design groups developed full-size clay models side by side in direct competition. Surviving photographs of the two models reveal that Tremulis’ clay design remained unchanged from his March 1947 advertisement proposal and was not chosen for production. The passenger side of the Lippincott team’s clay model (they submitted two designs), which incorporated the side profile developed by Tremulis prior to their arrival, was chosen virtually intact for the production automobile’s styling. Tremulis, like George Lawson, was eventually named the Tucker Corporation’s “chief stylist”.

The Car’s Engine:

The initial engine was a 589 cu. in. flat-6 cylinder with hemispherical combustion chambers, fuel injection, and overhead valves operated by oil pressure rather than a camshaft. An oil pressure distributor was mounted inline with the ignition distributor and delivered appropriately timed direct oil pressure to open each valve at the proper interval. Designed to idle at 100 rpm and cruise at 250-1200 rpm through the use of direct drive torque converters on each driving wheel instead of a transmission. This engine did not work out. The large 589 cu in engine functioned, but the valve train proved problematic and the engine only produced approximately 88 hp. The high oil pressure required a 24 volt electrical system and long cranking times at start-up. Having wasted nearly one year trying to make the 589 work, they started looking for alternatives. The 589 engine was installed only in the first prototype. (SN 1000) aka “The Tin Goose”.

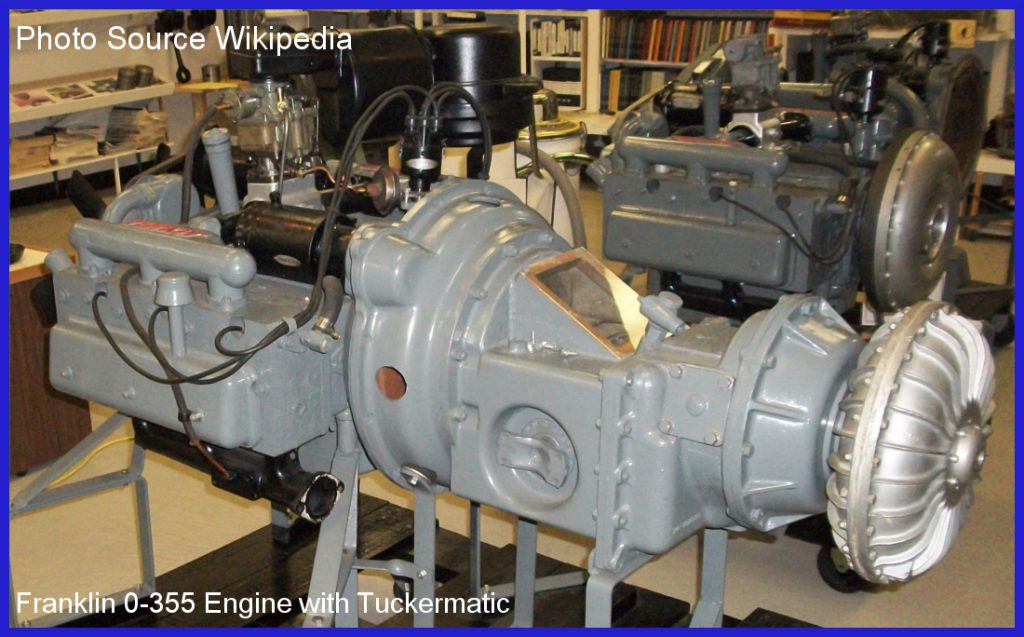

The alternative engine was a Franklin air-cooled flat-6 engine, the O-335 made by Air Cooled Motors (and originally intended for the Bell 47 helicopter). This 334 cu in, 166 hp Franklin engine was heavily modified by Tucker engineers, including a switch to water cooling (a decision that puzzled everyone since). Thus, very few parts of the original Franklin engine were retained, in the final Tucker engine design. This durable modification of the engine was tested at maximum power for 150 hours, the equivalent of 18,000 miles, at full throttle.

The car’s transmission:

Suspension:

Rather than springs, Tucker 48’s used an elastomeric (rubber) 4-wheel independent suspension. The rubber elastomers were developed with assistance from the Firestone Tire Company and used a special Vulcanization process to produce a specific spring rate. On cars #1001 and 1002 the rear wheels could not be removed due to the stiffness of the suspension and the rear wheel arch fender design. On cars #1003 & up the rear fender shape was changed so the tire could be removed easily. Aside from the fender changes, the rear suspension remained the same. The front suspension was installed in 3 versions, cars #1001–1002 used a rubber torsion tube design which suffered from severe toe-in during heavy braking. On cars #1003–1025, a rubber sandwich-type suspension (with a rubber block sandwiched between upper and lower A-arms) was used, however this type was severely stiff. On cars #1026 & up a suspension design using a modified version of the original rubber torsion tube, with the toe-in braking problem corrected, was used.